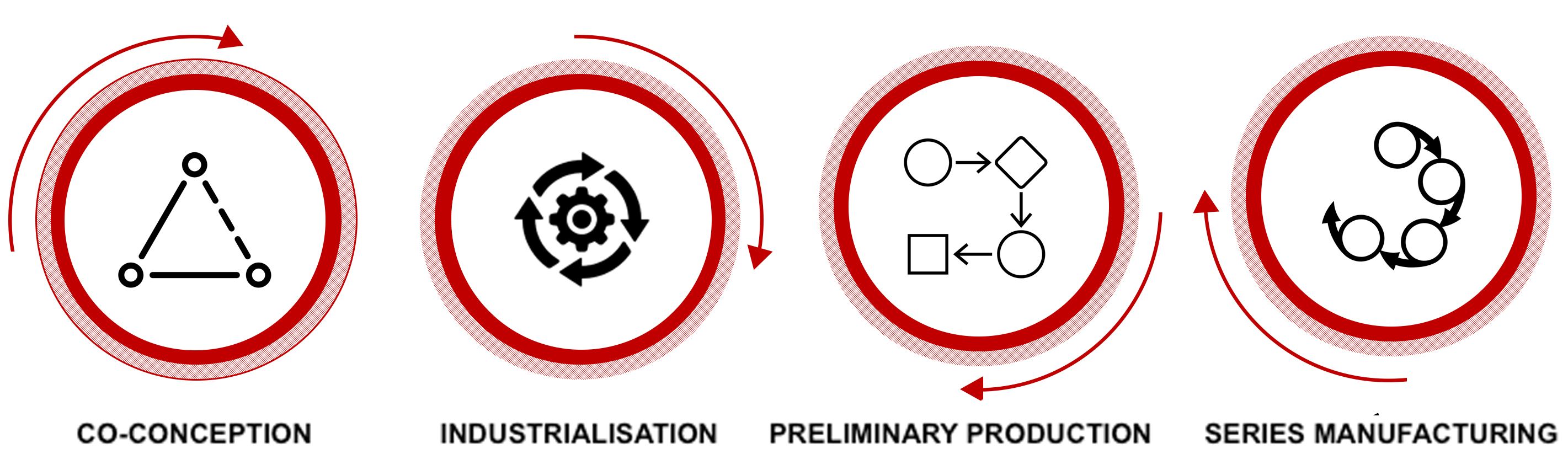

BECAUSE EACH PROJECT IS UNIQUE,

WE HAVE DEVELOPED A FOUR-STEP SUPPORT PROCESS

#1 CO-CONCEPTION

JEFMAG engineers conduct a feasibility study of your project.

The best match is determined between your needs and our machinery.

On the basis of your plans and requirements, your product is adapted in order to optimise its manufacturability in terms of technology, quality, cost and production time.

The design is then approved, with the further possibility of making a prototype with a view to series production.

#2 INDUSTRIALISATION

Production routings, operating processes and procedures are established.

Welding reports and welding parameters are approved under WPQR standards.

Tooling is designed, and then built by JEFMAG’s technical teams.

Optimal work parameters are qualified; robots and machining centres are programmed.

#3 PRELIMINARY PRODUCTION

The settings and adjustments of tooling and machinery programs are defined in order to optimise manufacturing and ensure its reliability.

The dimensions and conformity to requirements are confirmed.

The first of series production units out of JEFMAG workshops are presented and approved.

#4 SERIES MANUFACTURING

Production and logistics programs are implemented according to the customer’s needs (supply chain management, precise on-time deliveries, etc.).

Follow-ups on quality are carried out and reported at every stage of production.

Processes and organisation are optimised with the aim of maximising the value chain as a whole.